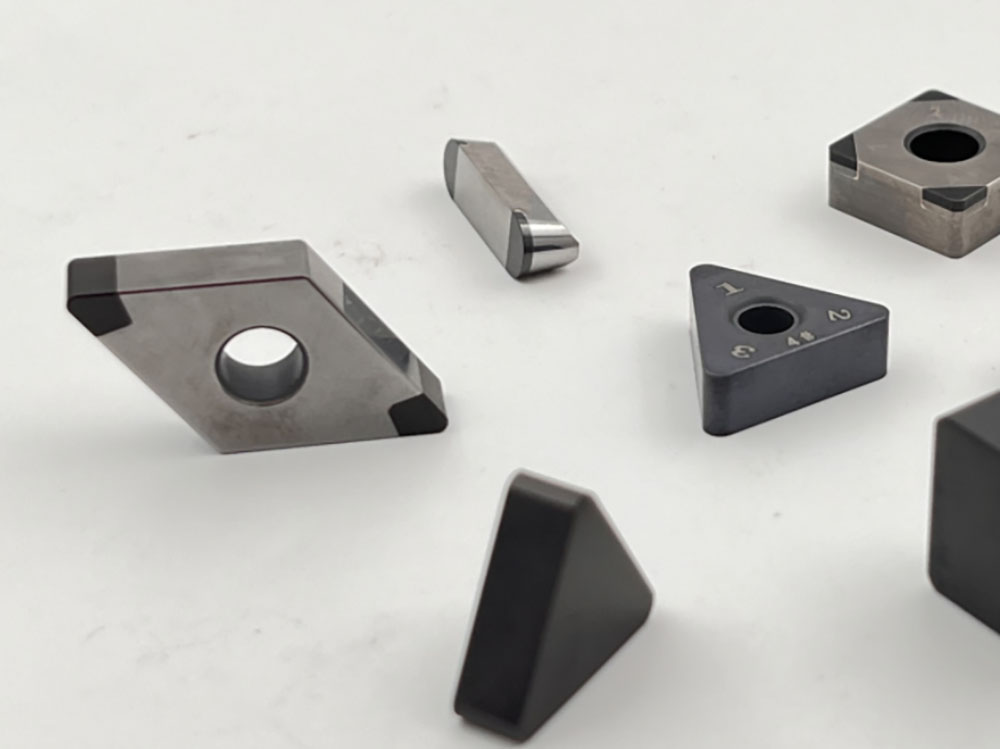

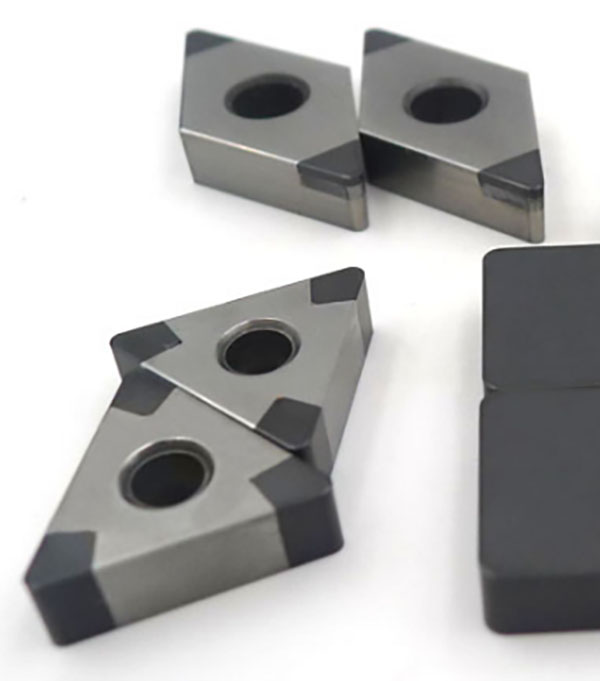

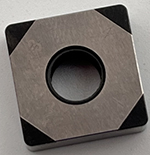

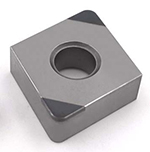

Slijtvaste polikristallyne diamantgereedskaplem van hoë gehalte en CBN-insetsel

CBN-insetsels het hoë termiese geleidingsvermoë en hoë stabiliteit, wat hulle in staat stel om hul eienskappe te behou by temperature tot 1400°C, waar diamante bo 800°C ontbind.CBN-insetsels is geskik vir hoë spoed sny en bewerking van hoë nikkel en chroom gietyster, motor remskywe, rem dromme, gietyster hubs, gietyster rolle, rollers en pompe, ens. CBN inserts kan oppervlak kwaliteit en akkuraatheid verbeter, verleng gereedskap lewensduur en verminder bewerkingskoste.

Produk voordele

Die mikrohardheid van CBN-enkelkristal is HV8000 ~ 9000, en die hardheid van PCBN-saamgestelde vel is oor die algemeen HV3000 ~ 5000. Daarom het dit hoër slytweerstand as harde legering en keramiek wanneer materiale met 'n hoë hardheid verwerk word, en kan die grootteafwyking in dele verminder verwerking.Dit is veral geskik vir toerusting met 'n hoë mate van outomatisering, en kan die bykomstigheid verminder

| Voeg vorm in | Tik | Graad | |||||||

| d | s | d1 | R | OPT850 | OPT005 | OPT010 | OPT302 | ||

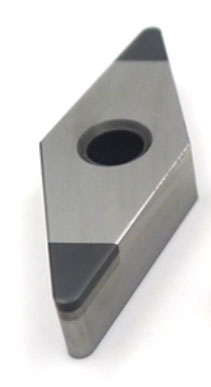

| VNGA160402 | 9,525 | 4,76 | 3,81 | 0.2 | ||||

| VNGA160404 | 9,525 | 4,76 | 3,81 | 0.4 | ★ | ||||

| VNGA160408 | 9,525 | 4,76 | 3,81 | 0.8 | ★ | ||||

| VNGA160412 | 9,525 | 4,76 | 3,81 | 1.2 | |||||

| VNGA220408 | 12.7 | 4,76 | 5.16 | 0.8 | |||||

| VNGA220412 | 12.7 | 4,76 | 3,81 | 1.2 | |||||

| VNGA160404-2 | 9,525 | 4,76 | 5.16 | 0.4 | ★ | ||||

| VNGA160408-2 | 9,525 | 4,76 | 5.16 | 0.8 | ★ | ||||

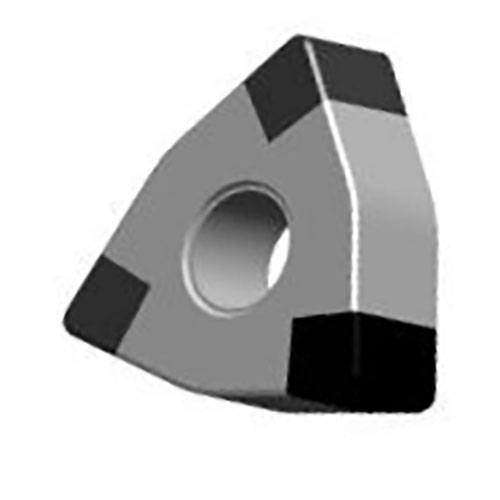

| Voeg vorm in | Tik | Afmeting (mm) | Graad | |||||||

| L | ¢IC | S | ¢d | r | OPT850 | OPT005 | OPT010 | OPT302 | ||

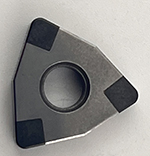

| WNGA06T304 | 6.5 | 9,525 | 3,97 | 3,81 | 0.4 | ★ | |||

| WNGA080408 | 8,69 | 12.7 | 4,76 | 5.16 | 0.8 | ★ | ||||

| WNGA080412 | 8,69 | 12.7 | 4,76 | 5.16 | 1.2 | ★ | ||||

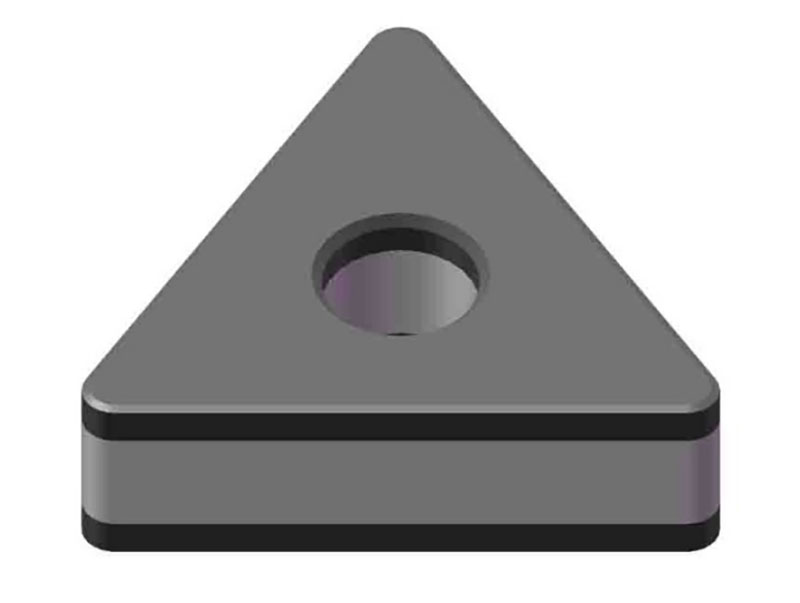

| Voeg vorm in | Tik | Graad | |||||||

| d | s | d1 | R | OPT850 | OPT005 | OPT010 | OPT302 | ||

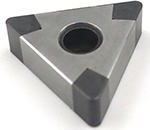

| TNGA160402 | 9,525 | 4,76 | 3,81 | 0.2 | ||||

| TNGA160404 | 9,525 | 4,76 | 3,81 | 0.4 | 〇 | ★ | |||

| TNGA160408 | 9,525 | 4,76 | 3,81 | 0.8 | 〇 | ★ | |||

| TNGA160412 | 9,525 | 4,76 | 3,81 | 1.2 | 〇 | ★ | |||

| TNGA160416 | 9,525 | 4,76 | 3,81 | 1.6 | |||||

| TNGA220404 | 12.7 | 4,76 | 5.16 | 0.4 | |||||

| TNGA220408 | 12.7 | 4,76 | 5.16 | 0.8 | 〇 | ★ | |||

| TNGA220412 | 12.7 | 4,76 | 5.16 | 1.2 | 〇 | ★ | |||

| Voeg vorm in | Tik | Graad | |||||||

| d | s | d1 | R | OPT850 | OPT005 | OPT010 | OPT302 | ||

| SNGA090304 | 9,525 | 3.18 | 3,81 | 0.4 | ★ | |||

| SNGA090308 | 9,525 | 3.18 | 3,81 | 0.8 | ★ | ||||

| SNGA120404 | 12.7 | 4,76 | 5.16 | 0.4 | ★ | ||||

| SNGA120408 | 12.7 | 4,76 | 5.16 | 0.8 | ★ | ||||

| SNGA120412 | 12.7 | 4,76 | 5.16 | 1.2 | |||||

| Voeg vorm in | Tik | Graad | |||||||

| d | s | d1 | R | OPT850 | OPT005 | OPT010 | OPT302 | ||

| CNGA09T302 | 9,525 | 3,97 | 3,81 | 0.2 | ★ | |||

| CNGA09T304 | 9,525 | 3,97 | 3,81 | 0.4 | ★ | ||||

| CNGA09T308 | 9,525 | 3,97 | 3,81 | 0.8 | |||||

| CNGA09T312 | 9,525 | 3,97 | 3,81 | 1.2 | |||||

| CNGA120402 | 12.7 | 4,76 | 5.16 | 0.2 | ★ | ||||

| CNGA120404 | 12.7 | 4,76 | 5.16 | 0.4 | ★ | ||||

| CNGA120408 | 12.7 | 4,76 | 5.16 | 0.8 | |||||

| CNGA120412 | 12.7 | 4,76 | 5.16 | 1.2 | |||||